Powder metallurgy

The company supplies tools to all of the large groups that manufacture sintered parts and is very active in terms of the latest developments in the utilization of materials and production processes. In the last few years TEMSA has advanced greatly, expanding facilities, machinery and staff dedicated specifically to this field.

Owing to this, powder metallurgy has become the sector with the largest growth within the company. With all of the accumulated experience, TEMSA now offers project design and advice in improving the processes of its clients.

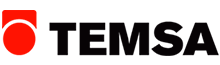

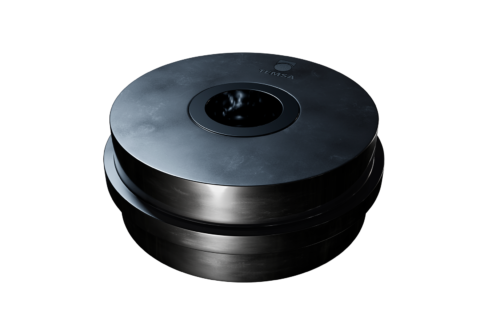

Shock absorver pistons and guides, rotors, gearboxes, pulleys and cams… TEMSA is highly focused on small parts, an area which isn’t possible for everyone, an area in which we’ve gained a lot of relevant experience over the years and we’re highly competitive.

Powder metallurgy

Powder metallurgy or sintering is a production process based on the compacting and sintering of metal powders in order to produce high quality parts with complex shapes, very narrow tolerances and in a cost effective way.

The parts are produced in two phases. First the metal powders are pressed, a mold formed by the tooling is filled using gravity and the press physically unites the powder particles at the closing of the cavity with the punch and the core applying high, one directional pressure which take on the shape of the cavity formed by the tooling.

Once ejected, the press is moved to a sintering furnace where it acquires the necessary physical characteristics.

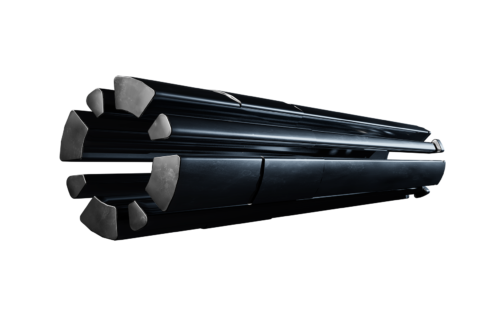

The tooling used in this process is special due to the preciseness of the production process, as much the punches as the core rods and pins must slide with the minimum clearance possible between them and the punches at the same time in the die to give the final shape to the part. The geometry of the tools must have regular contouring with tangent radii of 0.001mm in order for the tools to be as precise as possible.

Additionally, owing to the high pressure and friction of the process, adherence is the biggest obstacle to in elongating the lifespan of the tool. This is attained by applying the materials with the greatest features to protect against wear, which, depends on what it’s applied to, carbide or special steels. Always with perfect surface finishes with an Ra of less than 0.5.

TEMSA is specialized in the design and manufacturing of tooling for sintering small parts, such as the different damping elements – pistons and guides – as well as other elements for gears centered almost entirely in the automotive sector. From complete dies to a single part or even processes to reface used tooling, TEMSA is a flexible supplier and adapts to the needs of its clients.

COATINGS

In powder metallurgy, coatings are used to improve the qualities of any of the tool typologies. Each coating – TiN, TiAlN, AlCrN, among others – will provide specific supplementary qualities to the tool, be it the punch or the die. TEMSA works with the best companies in the coating application market to offer its customers the best options to increase the performance of their tools.

Cold forming

Cold forming is a technology with a great tradition, which continuously reinvents itself and surpasses new limits.

CARBIDE

TEMSA has developed and manufactured tools specifically for wear and cutting applications in different grades of tungsten carbide.