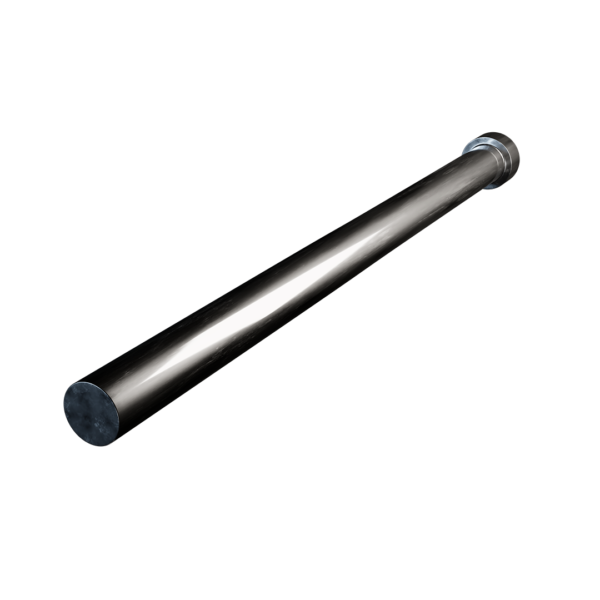

Core pins

Core pins have a very specific goal among the sintering tooling range, both in pressing and calibrating, and they require a high wear resistance in countless geometric shapes. TEMSA has been a world leader in the manufacturing of high precision tungsten carbide tooling for more than 30 years and is able to achieve high quality, high performance tooling for its partners.

TEMSA combines experience,

know-how and cutting-edge

technologies to achieve

the best tools for its partners.

Advice in steel and tungsten carbide qualities for several applications:

Advice in steel and tungsten carbide qualities for several applications:· Full tungsten carbide pins· 15%Co fine grain: when geometric shapes have sudden section changes.·12%Co medium grain: for svelte profiles with high risk of cracks.

· 9%Co submicron grain: the highest wear resistance.

· Full steel pins

· High strength powder metallurgical pins: combines cost savings and performance.

· Assembled tungsten carbide and steel pins

· Threaded assembly.

· Banded assembly.

· Brazed assembly.

Tooling reworking and maintenance.

Tooling reworking and maintenance. Possibility of adjustment with gauges.

Possibility of adjustment with gauges. Mirror polish in surface finishes.

Mirror polish in surface finishes.