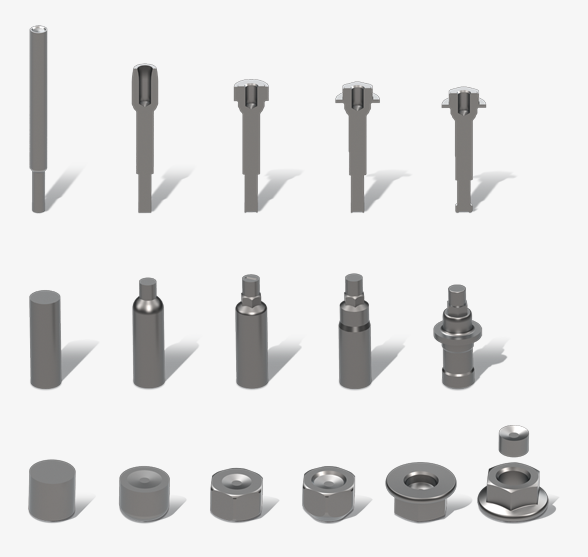

Engineering

The market is moving forward and TEMSA is always up to date in manufacturing and application technologies. All the experience accumulated by the company in the design of processes and tools is available to those who need it to solve the most complex challenges in stamping that, due to lack of time or know-how, can become difficult to achieve. A customer with their own resources.

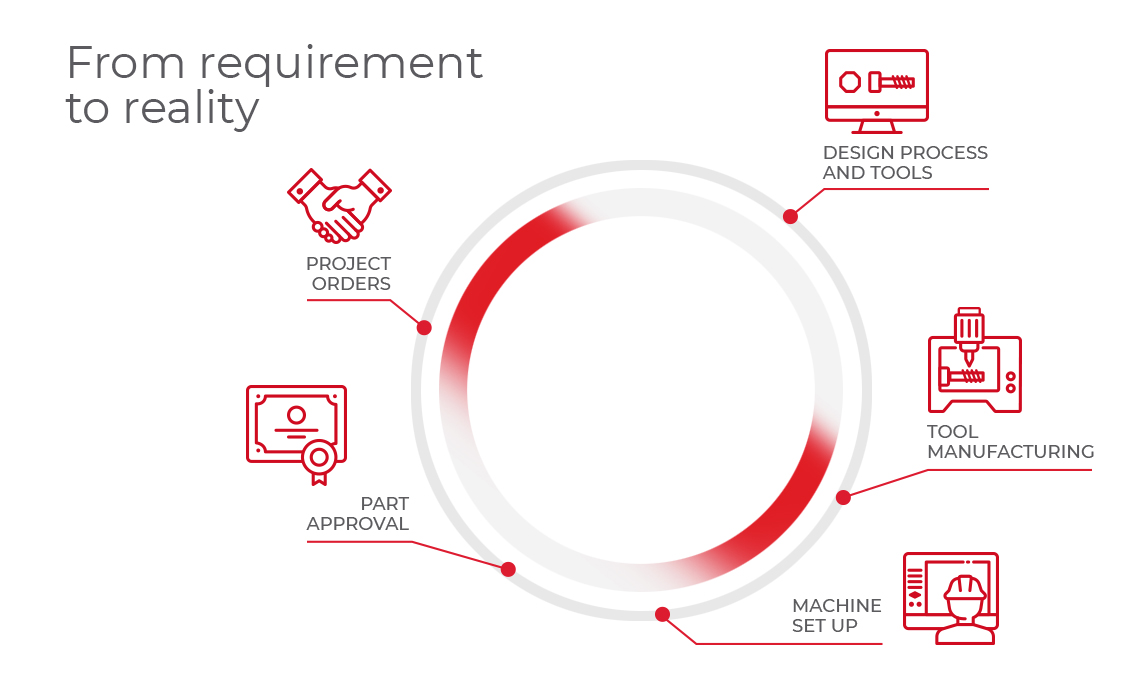

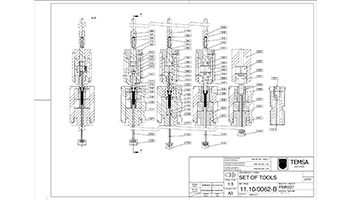

TEMSA offers the turnkey product development service that encompasses the design of the process and the cold forming tool, the manufacture of all the tools and the machine-put in the client’s home, and all this in record time.

It also has a team of 6 designers who perform technical assistance to solve specific problems in tool design processes and, if necessary, an outsourced technical office service.

Finished or semi-finished product, unit series or large series for high volume productions, shipments in 3 days or on call for deliveries spaced over time, TEMSA adapts the needs of all its customers.